|

ABOUT US

|

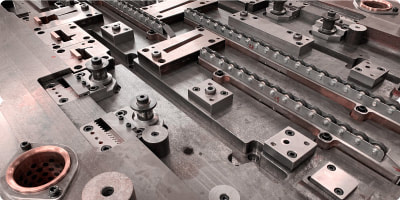

Bairrimoldes was founded in 1990 and has an experience of more than 25 years in tool manufacturing. In 2015 a new milestone was exceeded in the company´s growth, with significant supply of die sets for automotive 2nd tier. Acquisition of new facilities, operational equipment and critical HR has been involved. Currently, Bairrimoldes evolves, participates in and develops engineering solutions of greater complexity in progressive and transfer tooling systems for cold formed parts with advanced materials UHSS (Ultra High Strength). Final destinations are OEMs, e.g. VW group, Ford, BMW, GM.

OUR COMMITMENT IS TO ACHIEVE COMMON GOALS IN PARTNERSHIP

RECENT MILESTONES

In 2014 Bairrimoldes was definitively involved in higher value-added sectors, such as the specialized tiers of the automotive industry, by providing and participating in the tooling supply chain for sheet metal forming.

|

• Over the next years, the company has grown by 4x its turnover, which also reflects the qualitative step ahead in response to demanding solutions by the complexity and time-saving capacity of intervention with global metal manufacturing customers.

• Acquisition of numerical simulation capability and other support routines w/ an integrated development approach. New and merged internal team members in all departments. |

|

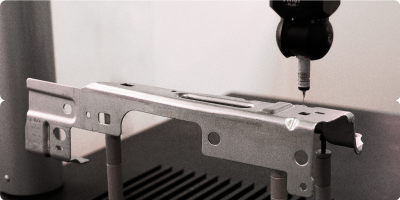

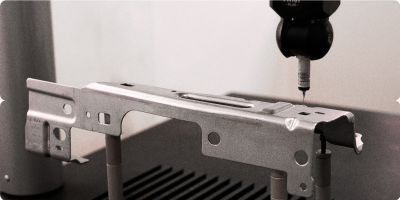

• Improving the Quality control with metrology technics and equipments – CMM and 3D Laser scan for measurement, inspection, machining validation and reverse engineering.

• R&D&I – Stepping up in 2016 with international Universities and R&D centers in co-authoring research projects of a step ahead in terms of advanced behavior for UHSS Dual Phase Steels, Martensitics, (...). Advanced tooling with study approaches for improved conformability. |

|

• In 2018 the first larger transfer die tool (6000 mm in two modules) and continuous tool projects for hotforming (blanks) cutting operations.

• In 2020 w/ new facilities of 1100 m2 and new improved CNC machinery up to table size of 5020x2400mm. Also new incoming developments for servo-press capacity. |